High Tensile Fasteners Has been included in our National 4 major assembly parts Technical Promoting Plan, Thus Boltec started from Equipment Improving, Technique Innovation and continuous improvement and research to develop appropriate Material, Production and Testing Equipment, Process Technology and tooling related to fasteners, aggressively promote our technical know-how and produce high-end products to replace imported fasteners. This is an incentive advantage at current economic environment for our company.

Our Advanced R&D Team with all kind of major specified product and process engineers obtained many IP technology and cooperate with China High Tech Promoting policy and Financial supports, we apply our developed technology to our current process equipment, extending tool life and efficiency, not only improved customers application efficiency but also provide cost-down opportunity to increase our customers competitiveness.

The auto industry competition in domestic market is increasingly fierce and the OEM become more strictly on quality and cost reduction request. The tiers must follow the footsteps of the industry to promote quality, cut down cost and shorten the product development cycle. They also need plenty of capacity to provide excellent product, logistics and technical service to the OEM so that they can gain market share.

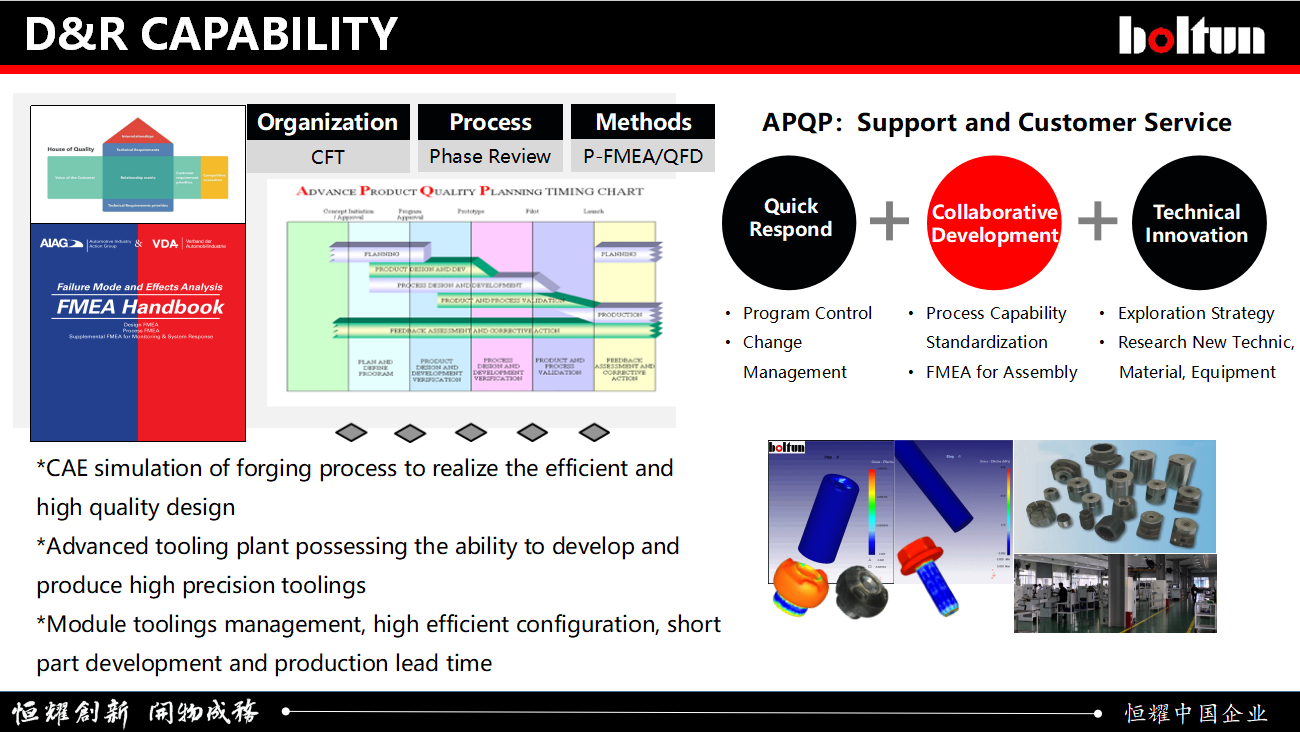

To meet customer needs, we would organize the core staff of different departments to identify the product families and feasibility, and make decision after evaluate the aspects that if the quality requirement can be meet, if the processing manner and cost have advantages, and if the lead time can be meet.

According to the customer needs and internal evaluation result, we would discuss the solutions on efficient quality inspection and control, processing manner and cost, development cycle to actively promote the product nomination.

In respect of part material, dimension, mechanical performance, corrosion resistance, inspection items, inspection manner, inspection equipment, packing requirements, application condition, and etc, we would make detailed evaluation and investigation to ensure the product fully meet customers’ needs.

According to products processing steps, material, machine, personnel, processing manner and production condition in process, production history of same family part and complaints information, we would assess potential failure mode, identify the severity, occurance and detection, and formulate prevention measures as to RPN order, to take effect, follow up the effective of the measures and keep improving.

Aimed at customers program schedule, we would plan the raw material, tooling, machine, personnel, place and subcontractor, formulate the development schedule, hold program meeting regularly to follow up the warning and review improvement.

In accordance with the FMEA, quality system and inspection ability, we formulate inspection items and control methods for products process, frame desirable control plan for special character, audit the implementation regularly, and actively invite customers to give advice and assist promoting quality level.

We submit qualified sample, formulate and submit the quality paper, inspection reports and kinds of warrant as customer’s request.

Actively participate the customers assessment process for the product, communicate to unify the inspection methods, cooperate to make fast improvement and optimization in connection with non-conformance while customers inspection and loading test, transmit the best practise to SOP.

Adopting the product prototyping and sampling history, formulate quality control methods applicable for lot production, Lean Production, bottleneck-breaking, and arrange the resources to supply both in quality and quantity according to MRP.